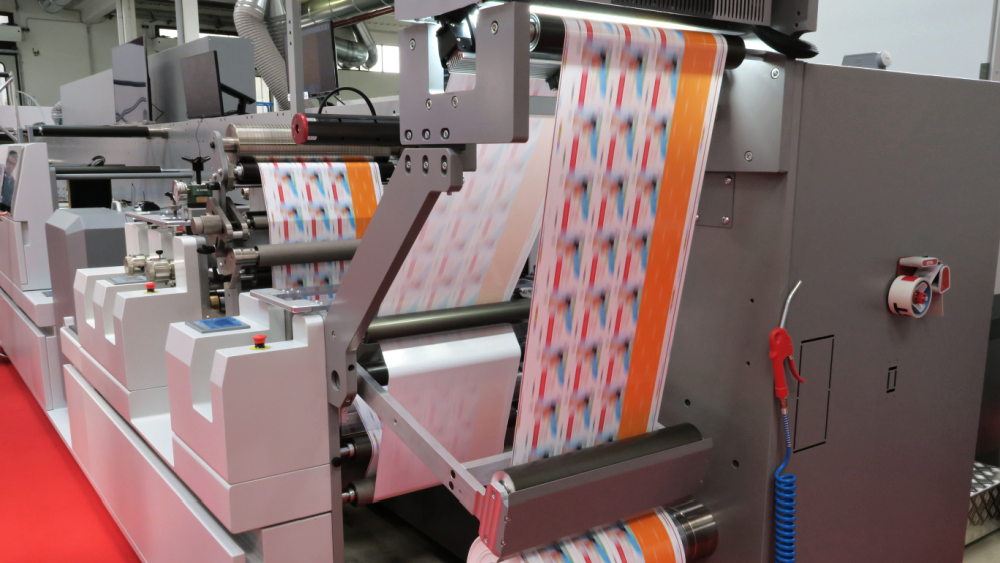

Creating a labelling solution often involves multiple stages, from design and printing to label application on packaging. Centralizing all labelling operations under one roof ensures that the final product meets both the brand owner’s and customer's expectations and regulatory requirements.

Labelling plays a crucial role in any industry, ensuring proper identification, tracking, and product branding. An effective label must also match the product and its lifecycle. Dispersing labelling operations across multiple suppliers can lead to delays, miscommunication, and inconsistencies in the final outcome. Gathering all operations under one roof contributes to overcoming these hurdles.

1. Faster production, quicker turnaround

In-house labelling production enhances efficiency in several ways:

- Speeds up production, especially for small batch orders and digital printing options such as VIP labels

- Enables quick and seamless adjustments to new product label designs

- Eliminates lag time – labels move from concept to application more quickly for faster turnarounds

2. Consistency and quality control

Consistency in branding is key to building trust and recognition. However, ensuring consistency across all product lines is a common challenge when using multiple suppliers for labelling operations.

Product categories such as Flexo, digitally printed labels, IML and Shrink sleeves all use different manufacturing techniques and processes. Using multiple vendors can lead to variances in quality.

A centralized approach offers a unified quality standard across all product labels, protecting the brand image and reducing costly errors. Quality controls also become simpler as teams are in close proximity.

Read more: 3 essential approaches to ensuring brand consistency

3. Greater flexibility for customization

Companies can quickly adapt to changing customer demands or market trends, offering customized labelling solutions without the delays associated with outsourcing. Whether it’s a limited-edition product, a special promotion, or an unexpected shift in customer demands, a one-stop solution offers the agility to create and test new designs on the spot.

4. Environmental and financial benefits

Bulk purchasing and reduced transportation lower carbon emissions, shrinking the overall carbon footprint. Additionally, streamlined processes reduce waste, further contributing to reaching sustainability goals.

5. More room for innovation

Having the design, production, and application teams in one space fosters collaboration and innovation. Teams can test new techniques, materials, and technologies, which can drive continuous improvement and keep the company at the forefront of industry advancements.

Read more: Rethinking packaging in the circular economy

In short, combining all labelling operations under one roof ensures smoother processes, faster delivery times, and better quality control – all while supporting a sustainable and adaptable business model. For any brand looking to stand out and stay ahead, centralizing labelling operations is a step worth taking. Contact us for a friendly chat about all-inclusive solutions that can elevate your product labels.