Material consumption

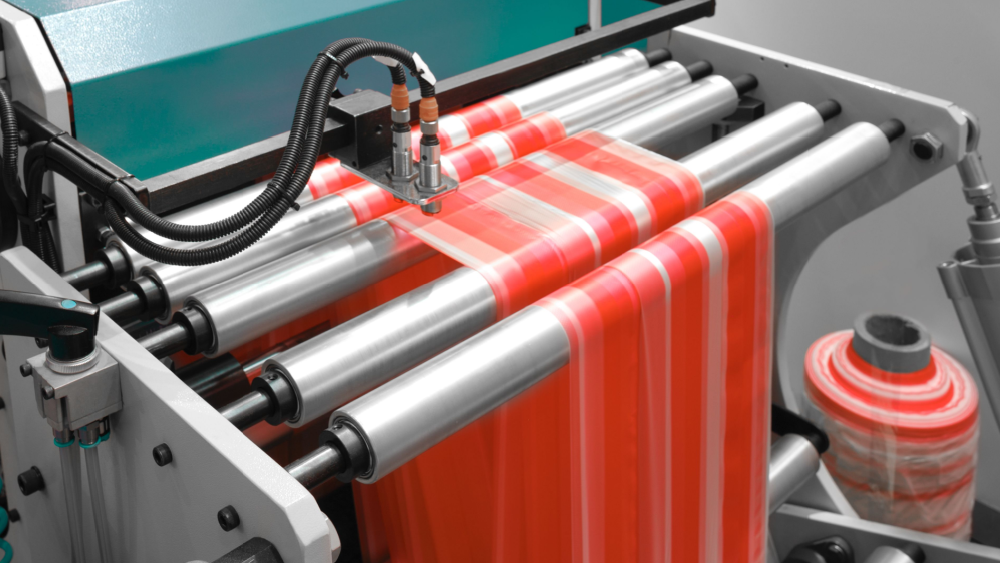

Within the labelling and packaging industry, the two main sustainability concerns revolve around the material being used and the amount of waste generated.

We strive towards eliminating these issues here at Skanem India and have put measures in place to ensure more sustainable manufacturing:

- Undoubtedly, the greatest contemporary challenge is the need for alternate, sustainable materials. Not surprisingly, the cost is a large part of that equation and can be a major obstacle. Nowadays, all prime label stock suppliers are committed to sustainability and are working towards environmental goals. As more alternative materials become available, prices will decrease.

At Skanem India, providing sustainable choices involves being sensitive to the customer’s voice. Part of this involves testing and validating sustainable product options in collaboration with customers and suppliers, to find the best suitable packaging. - Reducing or eliminating material wastage should be implemented in all stages of the manufacturing process. It is essential for achieving higher sustainability levels. There also needs to be a focused approach toward reducing print setup wastage and defects generated while printing.

- Last but not least, a primary sustainability goal for any manufacturing plant should be segregating and recycling different wastage types generated during production. Although this can be challenging, having the right converters and suppliers on board will make it easier to reach the set sustainability goals.

Read more: Do you have a sustainable packaging and labelling strategy?

Energy consumption

Due to changes in the supply-demand ratio, energy costs are increasing annually. Reducing energy consumption is, therefore, not only a cost-effective measure but also a means of reserving energy for the future.

At Skanem India, we have identified potential energy-saving opportunities for the manufacturing process:

- Switching to LED lights for all lighting is one way to go. However, it is possible to take this one step further and apply LED curing systems for printing technologies as well. This is a considerable move toward sustainable manufacturing! We have already installed many LED-ready curing systems in the recent past and are now ready to take on this sustainability goal.

- Rooftop solar power is another significant energy-saving measure. Solar power provides heaps of green energy, contributing to more sustainable manufacturing. Our goal at Skanem is to set up a solar unit to meet at least 50% of the total energy requirement.

- Automated device switching and power factor optimization contribute to cumulative energy savings. While these measures may be less significant on their own, they work wonders when implemented on a larger scale. Our engineers at Skanem are currently working on these types of projects to ensure that the production of labels and packaging is as green as possible.

Read more: 3 ways to enhance productivity with an automated labelling machine

Ultimately, to achieve a sustainable manufacturing process, we need to reduce the high material and energy consumption levels. Starting with the opportunities that exist today, it is possible to find even better eco-friendly and cost-efficient options in the near future.

At Skanem India, we continuously strive towards greener manufacturing to ensure sustainability for your product’s packaging and label. Feel free to contact us if you have any questions.