Label applicators and machines are designed with different functionalities for various usage areas. Factors such as the dimensions of your product and label play a prominent role in choosing the right machine. Meeting the necessary requirements will help you achieve your intended results.

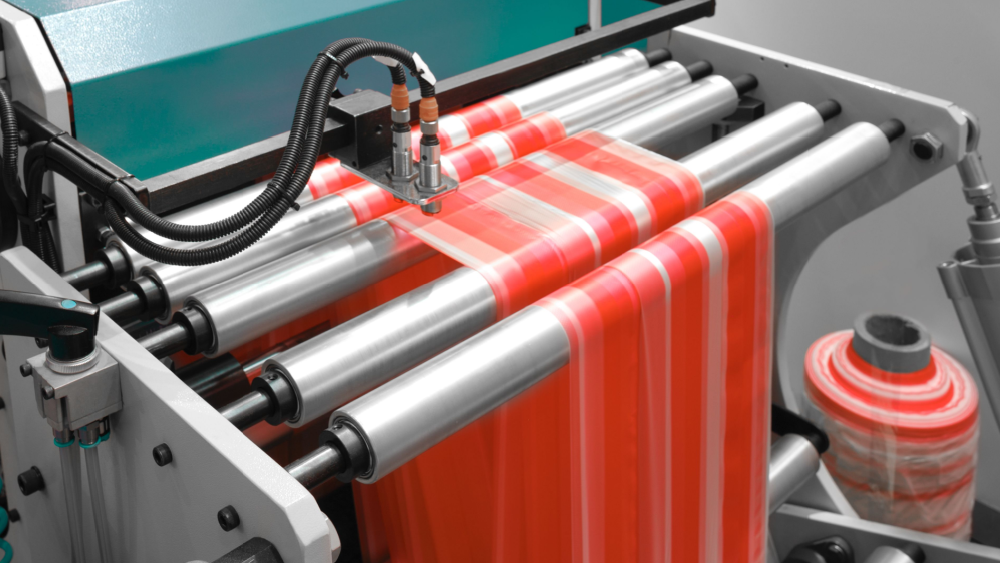

Labeling machines and applicators automatically apply pressure-sensitive labels onto products. Labels are rolled into the machine and threaded through path rollers, peeling blades, nip rollers, and rewinding rollers. The peeling blade first peels the label and applies it, followed by a suitable massaging mechanism that ensures proper label adhesion to the product.

However, the machines can only do the job correctly if specific criteria and requirements are met. Choosing the correct functions is one requirement, but product type, surface, and label material also impact how the labels turn out.

Types of label applicators

A well-built, thoughtfully designed label applicator is, first and foremost, easy to operate, fast, and accurate. It will also quickly recoup its cost with time, providing a return on investment by reducing the need for manual labour while still increasing the output rate. But choosing the right system is essential for realizing all these benefits.

Here are some of the various label applicators available at Skanem India:

Automatic label applicators

All automatic labelling machines and applicators are directly integrated or installed in an existing product handling system. Examples include:

- Front and back labelling

- Wrap-round labelling

- Top and bottom labelling

- Combination of any of the above

Semi-automated label applicators

Semi-automated label applicators require an operator to place the product into a fixture, mandrel, or jig assembly and then apply the label with a foot pedal. These label applicators often feature a tabletop design for added portability and ease of use. They can also apply labels to round bottles, flat bottles, and tubes.

Stand-alone label applicators

Stand-alone label applicators can be integrated or installed into the customer’s existing product handling systems.

Read more: Applicating Lean Six Sigma in the printing industry

Choosing the right label applicator

Above all, a labelling solution should enhance production and be cost-effective. The equipment must perform at the necessary application speed, reduce labour costs, and earn back its value with time. However, beyond these concerns, you should consider certain technical requirements when selecting a label applicator.

Product surface

It’s important to ensure the label applicator can handle different packaging shapes. Think about whether it can be applied to flat, concave, convex, or some other, more irregular shapes.

Label sizes

Consider the minimum and maximum size of the label to be handled.

Label location capability

Once it’s been verified that a label applicator can accommodate the shape and dimensions of a label, it should also be capable of applying it to the desired surface of the product. This could be at the top, bottom, front, or back of the product, or a combination of those.

Label Material

The label applicator also needs to work well with the label material, whether that’s paper, film, foil, or some other material.

Application rate

Application speeds, measured in products per minute, are also an important aspect.

Accuracy requirements

Lastly, your label applicator should be capable of applying the label within specified limits (positional accuracy) for all products.

Read more: 5 things to consider before designing your new labels

No matter your labelling needs, we have solutions to ensure you achieve your intended results. Contact us if you have any inquiries about choosing the right labelling machine for your product – our team are happy to help you along the way.